| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : BLM

Place of Origin : Jiangsu, China

MOQ : 5 sets

Price : Fob Shanghai USD800-3500/set

Payment Terms : Western Union, T/T

Supply Ability : 500 sets per Month

Delivery Time : 45-70days subject to the clients' requirement and quantity

Packaging Details : packed and labeled according to the regulations and customer's requests.Great care is taken to avoid any damage which might otherwise be caused during storage or transportation.

Model Number : BLM-E

Size : standard or customization

Type : Extrusion parts

Application : plastic processing

Delivery : 45~90days subject to the clients' requirements and quantity

Material : Die steel M2/D2(hardness about HRC60); Hot isostatic pressing HIP5 (WR5) SAW39, X260 (equivalent to Wr14, SAW26)

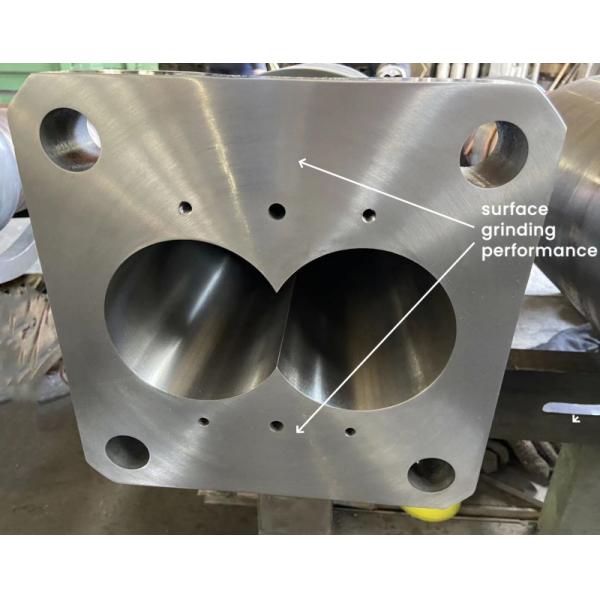

Alloy Steel Twin Screw Extruder Barrel

The barrel and bushing are extremely important components in the twin-screw extruder process. They need to be applied in different production environments and must have sufficient pressure-bearing capacity. Due to the impact of corrosion and friction, bushings are usually placed inside the barrel. When the wear is severe and replacement is necessary, simply replace the bushing.

Function

The main function of the extruder barrel is to house the screw and provide a confined space for the material to be processed. As the screw rotates, it moves the material forward through the barrel, where it is heated and melted or softened for extrusion.

Detailes

Prodcution process

Package and shipment

Applications

1. plastics processing

2. rubber manufacturing

3. food extrusion, and more.

FAQ

1.How do Iknow if my screw or barrelneeds replacement?

signs of wearinclude decreased performance,increased energy consumption,and noticeable damage to the screw flights or barrel surface.

2.what are the common causes of wear in extruder screws and barrel?

common causes of wearinclude abrasive materials,high temperatures,and prolonged usage without proper maintenance.

3.How to optimize the performance of my injection screws?

optimizing performance involves regular monitoring ofwear,adjusting materials, and considering upgrades or enhancements such as coatings or design modifications.

4.What measures can be taken to minimize wear in feed screws for plastic extrusion?

Minimizing wearinvolves selecting appropriate materials,improve design, maintaining proper alignment,and implementing preventve maintenance schedules

5.How does wear in conical screws impact the efficiency of mixing and compounding processes?

Wearin conical screws can result in uneven mixing,reduced throughput,and increased energy consumption,affectng the efciency ofmixing and compounding processes.

|

|

Alloy Steel Twin Screw Extruder Barrel for Reinforced Compounds Images |